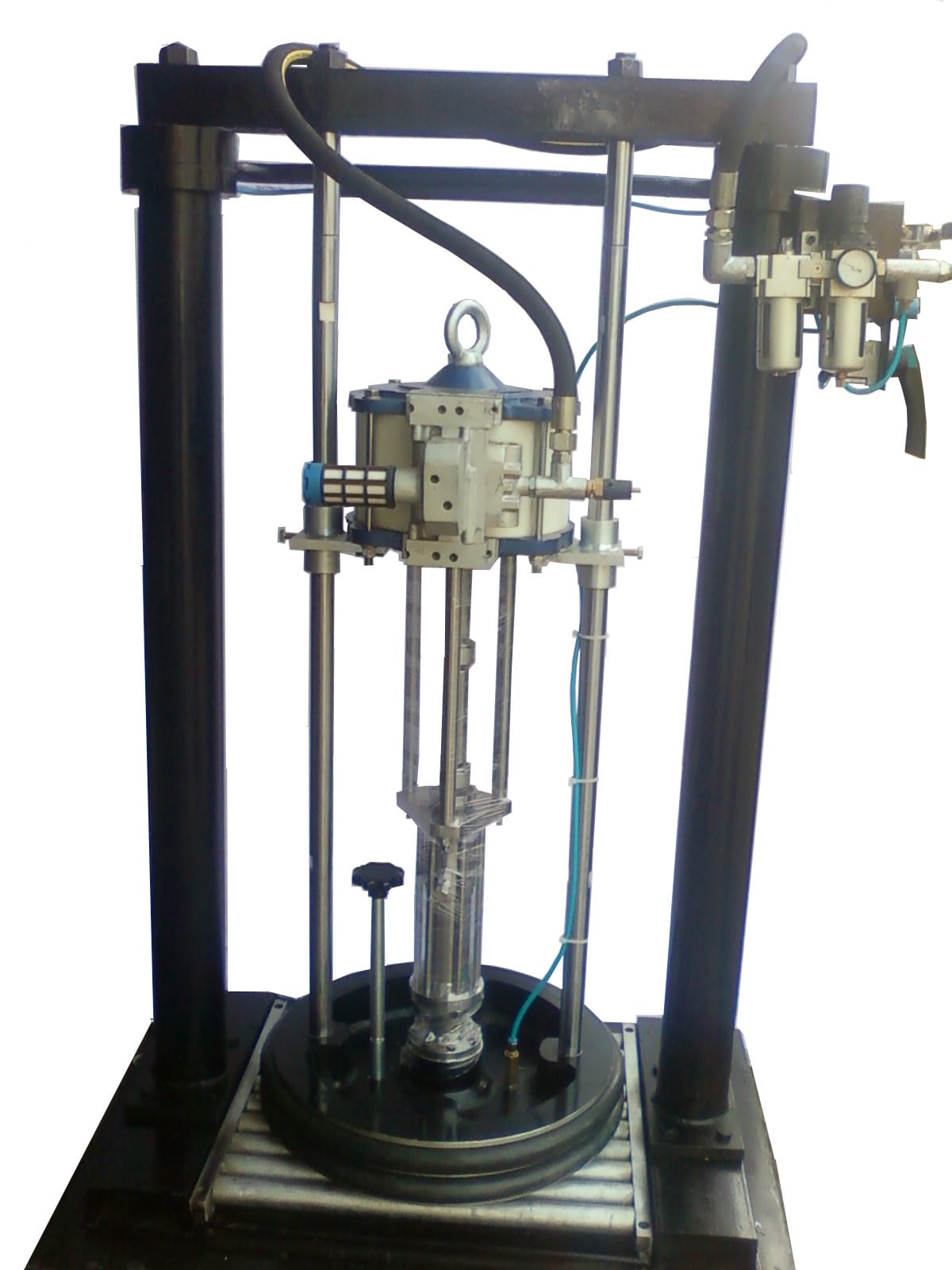

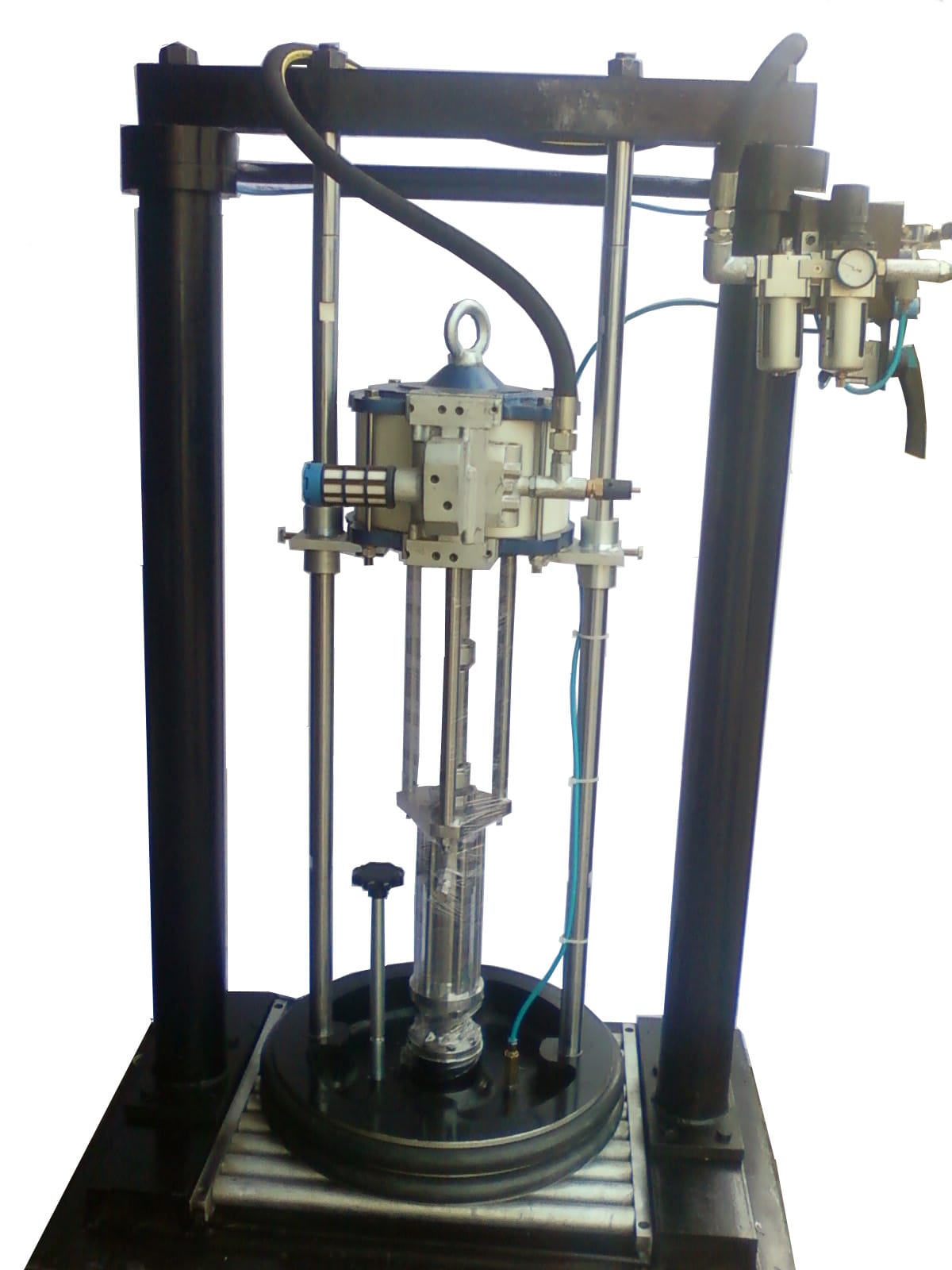

Drum Press

- PRODUCT

- Drum Press

Structure:

- Drum presses are usually heavy-duty machines built with robust materials such as steel to withstand the force exerted during the compaction process.

- The main structure consists of a frame that supports the hydraulic or mechanical components responsible for compressing the drums.

Compression Mechanism:

- Drum presses employ hydraulic or mechanical mechanisms to apply pressure to the drums, compacting them and reducing their volume.

- Hydraulic drum presses use hydraulic cylinders powered by hydraulic fluid to exert force on the drums.

- Mechanical drum presses may use a screw mechanism or a lever system to achieve compression.

Loading Mechanism:

- Drum presses typically feature a loading mechanism that allows operators to easily place drums onto the press for compaction.

- This can involve a hinged loading gate or platform that can be raised and lowered for loading and unloading drums.

Control System:

- Modern drum presses are often equipped with electronic control systems that allow operators to regulate the compaction process.

- These control panels may include buttons or touchscreen interfaces for adjusting parameters such as pressure, cycle times, and safety features.

Safety Features:

- Safety is paramount when operating drum presses due to the high forces involved.

- Safety features may include emergency stop buttons, safety guards, interlocks to prevent operation when guards are open, and pressure relief valves to prevent overloading.

Output Mechanism:

- Once drums are compacted, some drum presses feature mechanisms for ejecting the compacted drums.

- This could be a hydraulic ram that pushes the compacted drums out of the press, or a manual mechanism for removing them.

Size and Capacity:

- Drum presses come in various sizes and capacities to accommodate different types and quantities of drums.

- Some drum presses are designed to handle standard 55-gallon drums, while others can handle larger or smaller drums.

Mobility:

- Depending on the specific application, some drum presses may be stationary, while others are mounted on wheels or casters for mobility within a facility.

Maintenance Requirements:

- Like any industrial equipment, drum presses require regular maintenance to ensure optimal performance and longevity.

- This may include lubrication of moving parts, inspection of hydraulic components, and replacement of wear parts.